外包制造¶

Outsourcing a portion or all of your company’s manufacturing needs is not easy. To make it work correctly, you have to:

Manage the inventory of raw materials at your subcontractor

Ship raw material to your subcontractors, at the right time

Control incoming goods quality

Control subcontractors bills

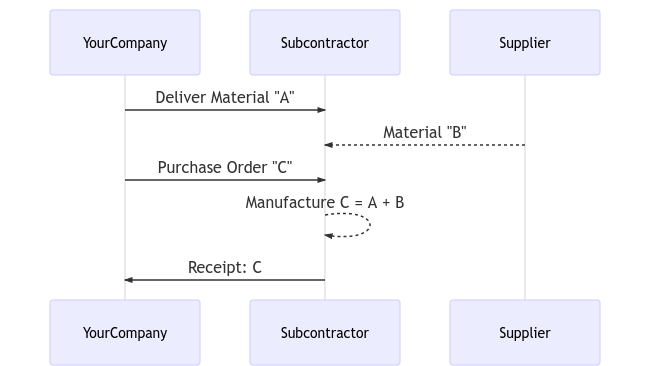

这是转包制造“C”的例子,它是用原材料“A”和“B”生产的。

With its MRP subcontracting feature, Odoo helps you handle this flow easily.

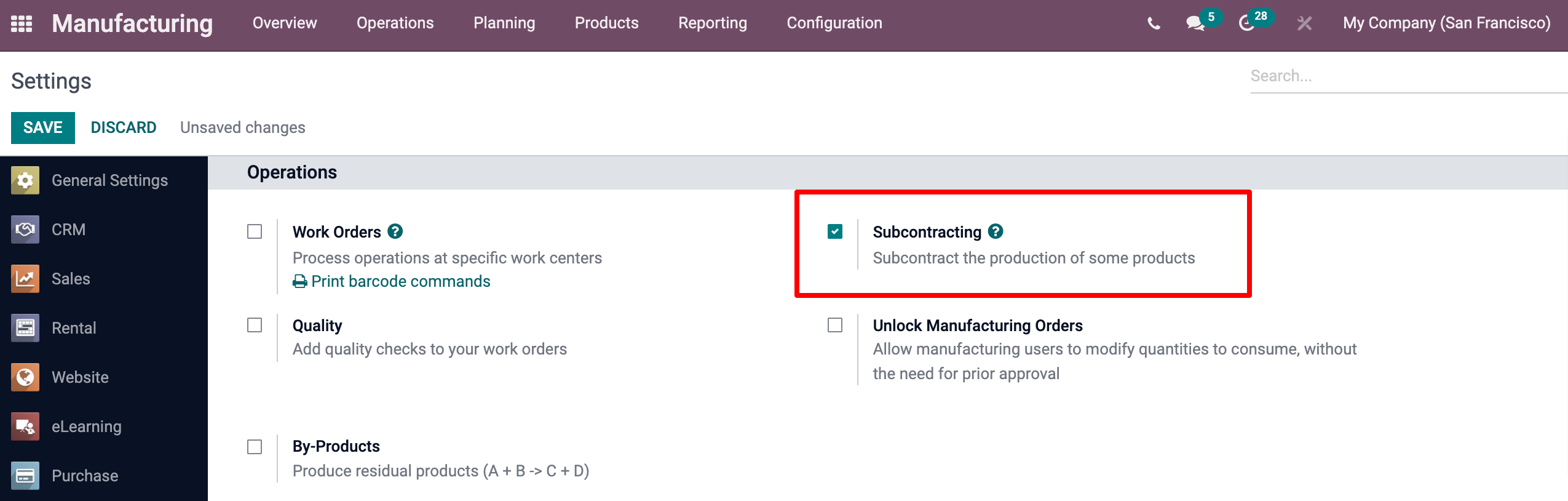

基础配置¶

要使用转包功能,请转到 :menuselection:`制造 –> 配置 –> 设置并勾选 转包 。

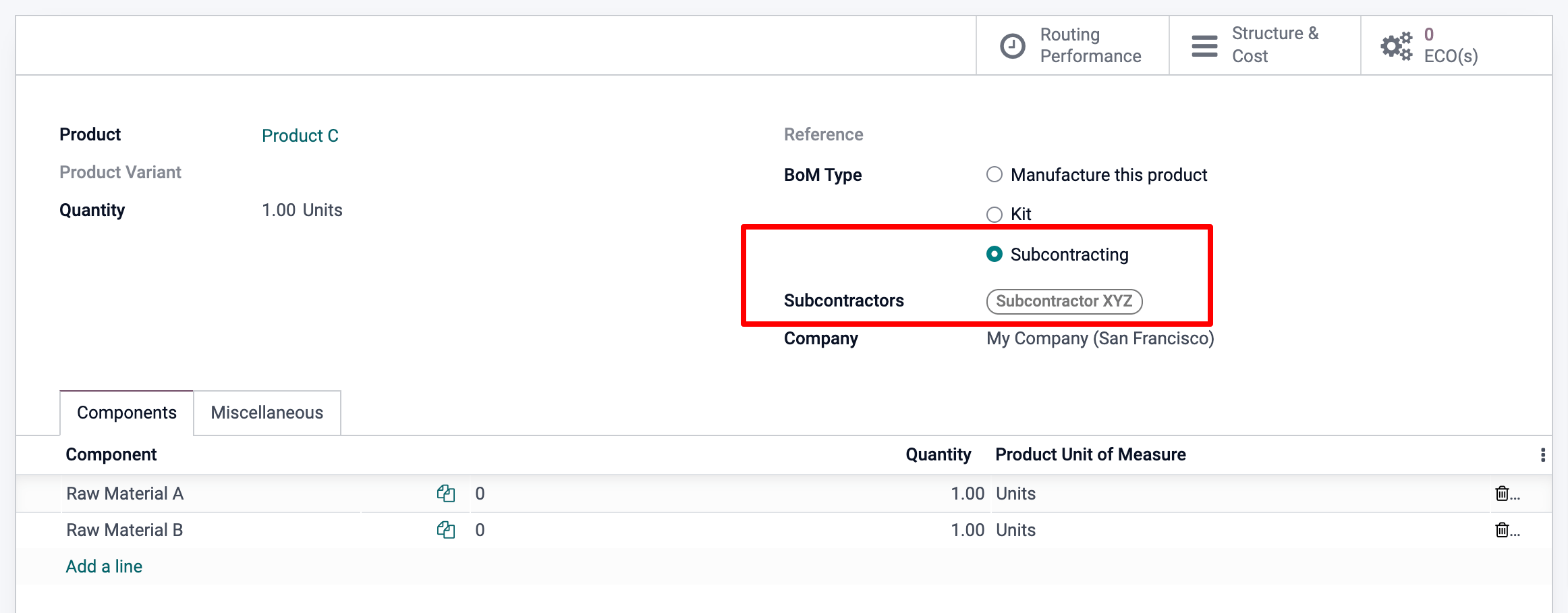

要定义一个产品是否必须分包,使用类型 分包 的 物料清单(BoM) 。

To create a new BoM, go to and hit create. Then, list the components your subcontractor needs to manufacture the product. For costing purposes, you might want to register all the components, even the ones that are sourced directly from the subcontractor.

将 BoM类型 设置为 转包 后,指定一个或多个转包商。

基本分包流程¶

To let your subcontractor know how many products you need, create and send them purchase orders (PO). To do so, go to the Purchase app and create a new purchase order. Be sure to send the PO to a vendor that is defined as a subcontractor on the BoM of these products.

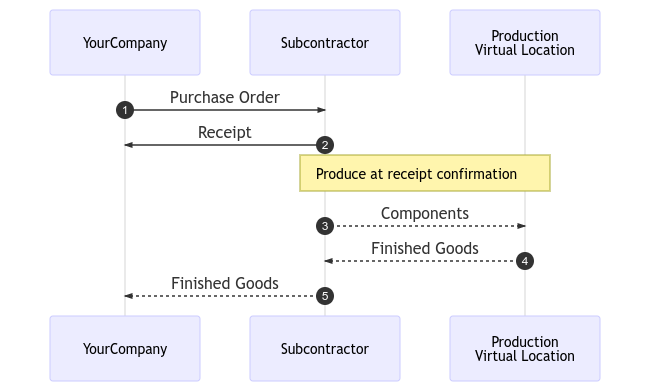

Once the PO is validated (1), a pending receipt is created. When the products are received, validate the receipt (2), with the actual quantity received. As a result, Odoo does the following things for you:

Consumes the respective components at the subcontractor’s location, based on the BoM and your input (3);

Produces the finished goods at the subcontractor’s location (4);

Moves products from that subcontractor’s location to YourCompany via the validated receipt (5).

注解

The PO is optional. If you create a receipt manually, with the right subcontractor, Odoo still performs all the moves. This can be useful if the subcontractor does not bill a fixed price per item, but rather the time and materials used.

库存计价¶

制成品“C”的成本定义为:

C = A + B + s

与:

A :来自贵公司的原材料成本;

- B :直接从采购的原材料成本

分包商;

s :分包服务的成本。

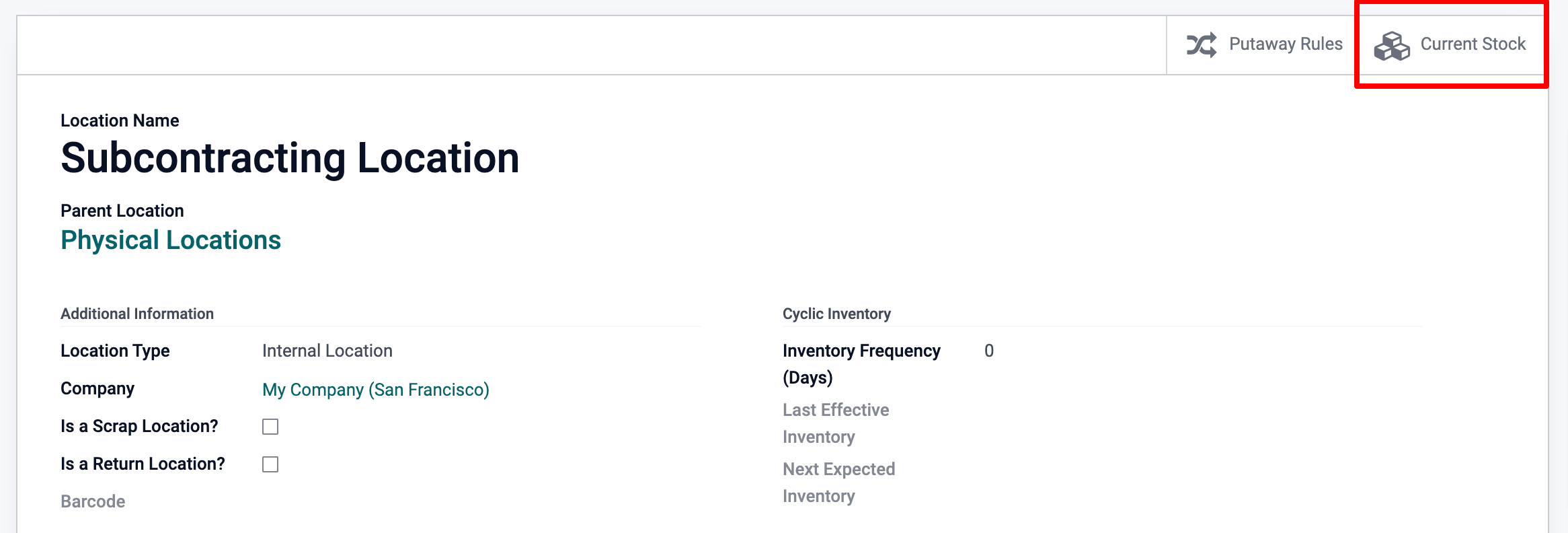

Sending raw materials to your subcontractors (A) does not impact the inventory valuation, as the components are still valued as part of your stock. This is managed by making the Subcontracting Location an Internal Location.

然后,在产品C表格上设置的卖方价格必须是分包商为其零件和服务时间所必须支付的价格: ** B + s ** 。 产品成本必须为:A + B + s ,该产品在会计中的价值。

Finally, the subcontractor bill then matches the purchase order, with the proposed price coming from the finished products C.

注解

如果不需要在你的分包商所在地管理原材料的补充,只需在分包商的价格中包括 B 的成本,并将产品从 BoM 中删除。

追溯¶

In case the received products from the subcontractor contain tracked components, their serial or lot numbers need to be specified during the receipt.

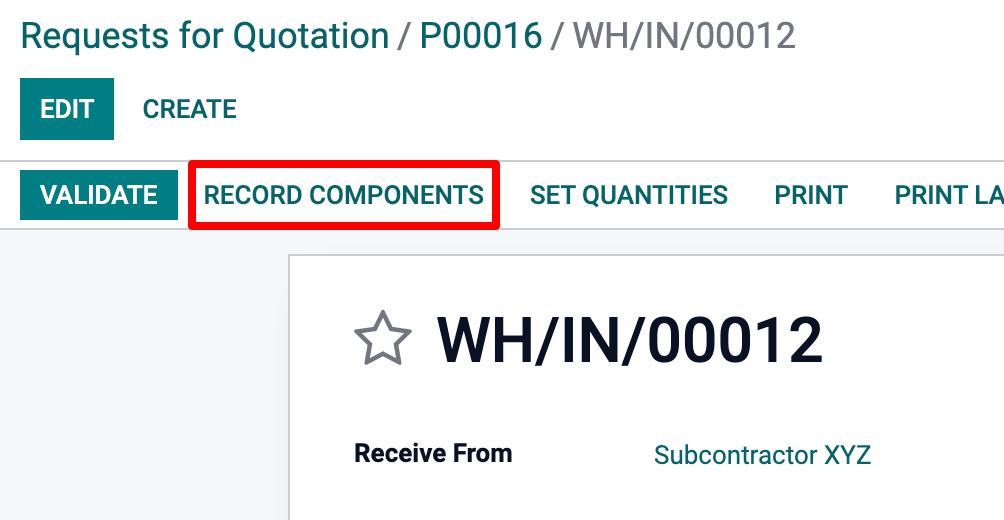

In that case, on the receipt of the subcontracted product, a Record Components button appears. Click on it to open a dialog box and record the serial/lot numbers of the components. If the finished product is also tracked, its serial/lot number can be registered here too.

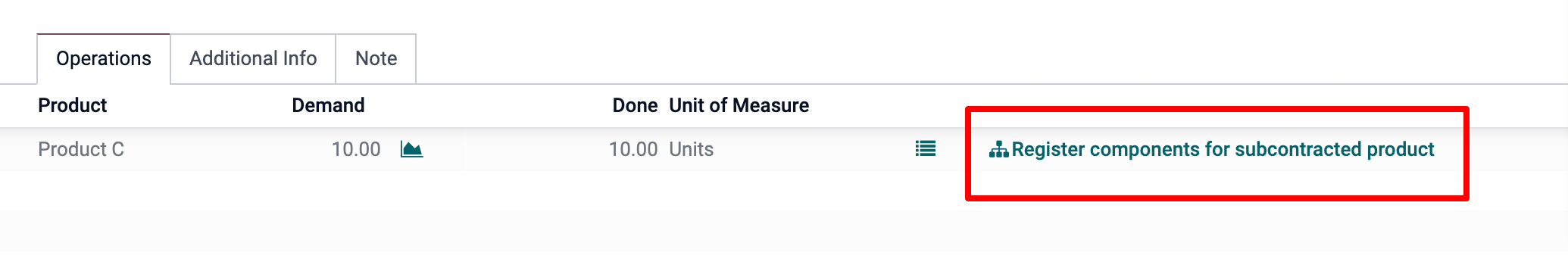

出于审计目的,可以使用成品右侧的图标检查收据上记录的批号:

Also note that in case flexible consumption has been selected on the subcontracted BOM for a non-tracked product, the record components option will also appear optionally on each move line, if you want to register more or less component consumption at your subcontracting location, when receiving your final product.

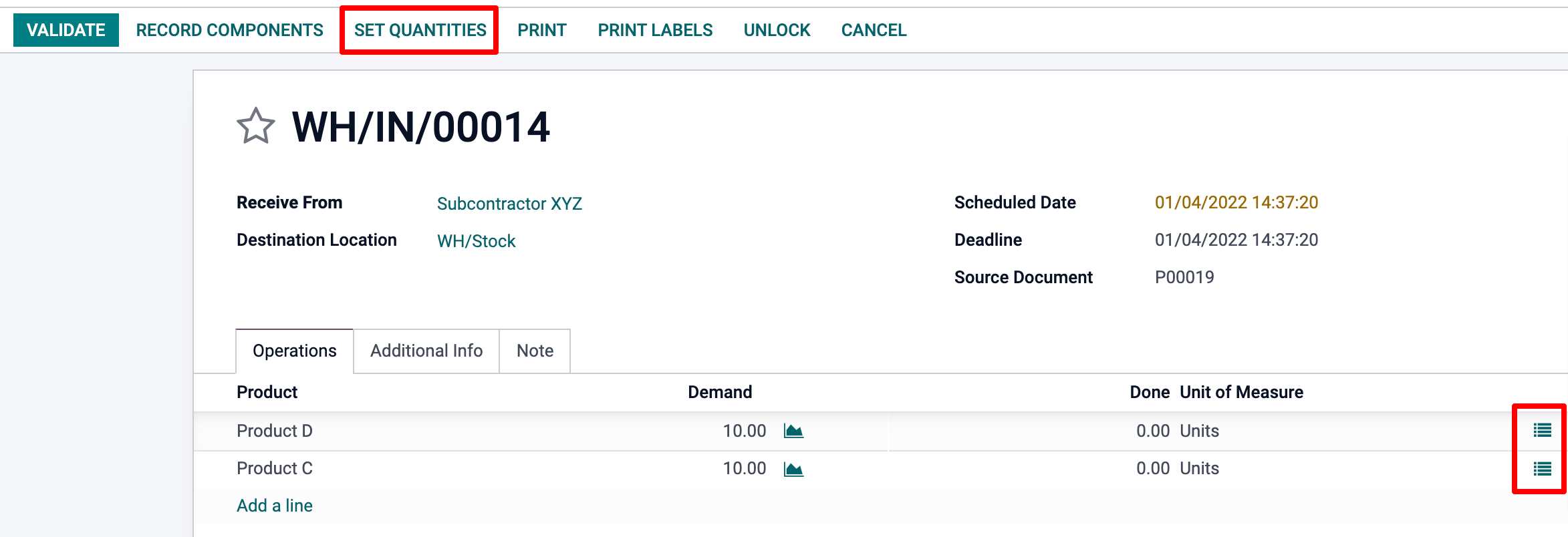

As you can see, the reception of both of these non-tracked products can either be executed by selecting the ‘Set Quantities’ Option or via the move line hamburger menus.

分包商的自动化补货¶

There are two ways to automate the supply of raw materials to your subcontractors when purchasing the final product. The chosen method depends on whether or not you want the materials to transit through your warehouse. Both of these methods are described as pull style mechanisms as their trigger is the inital PO to the subcontractor, which creates a need at the subcontracting location, for raw material.

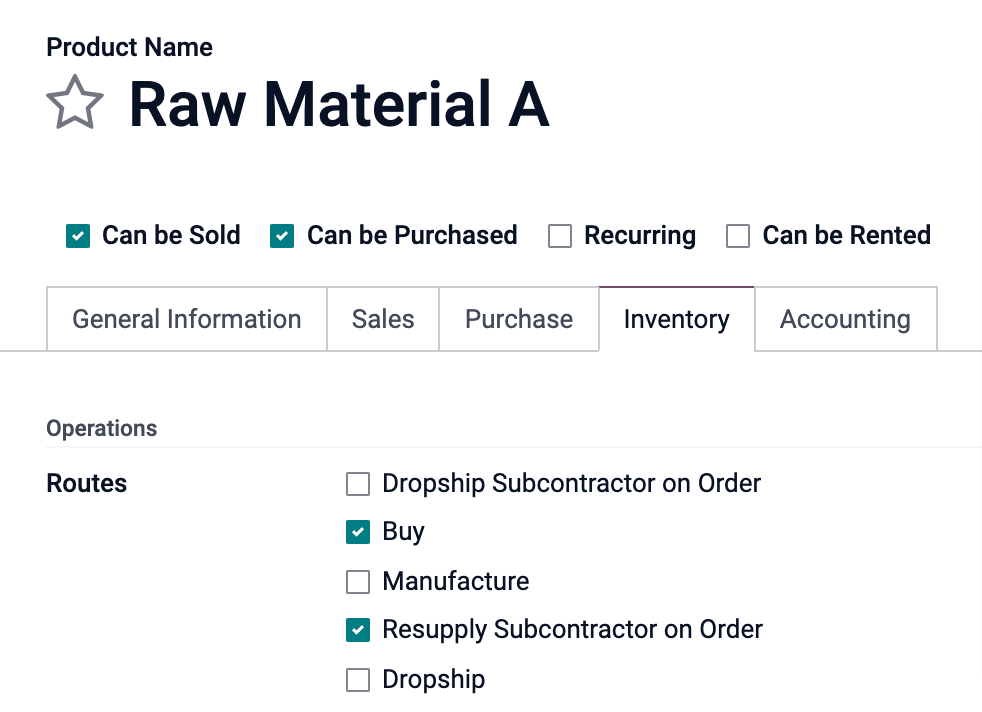

If you are supplying your subcontractor with raw material from your own warehouse, you must activate the ‘Resupply Subcontractor on Order’ route as shown below. If this is a component that you buy from a vendor, the buy route should also be activated.

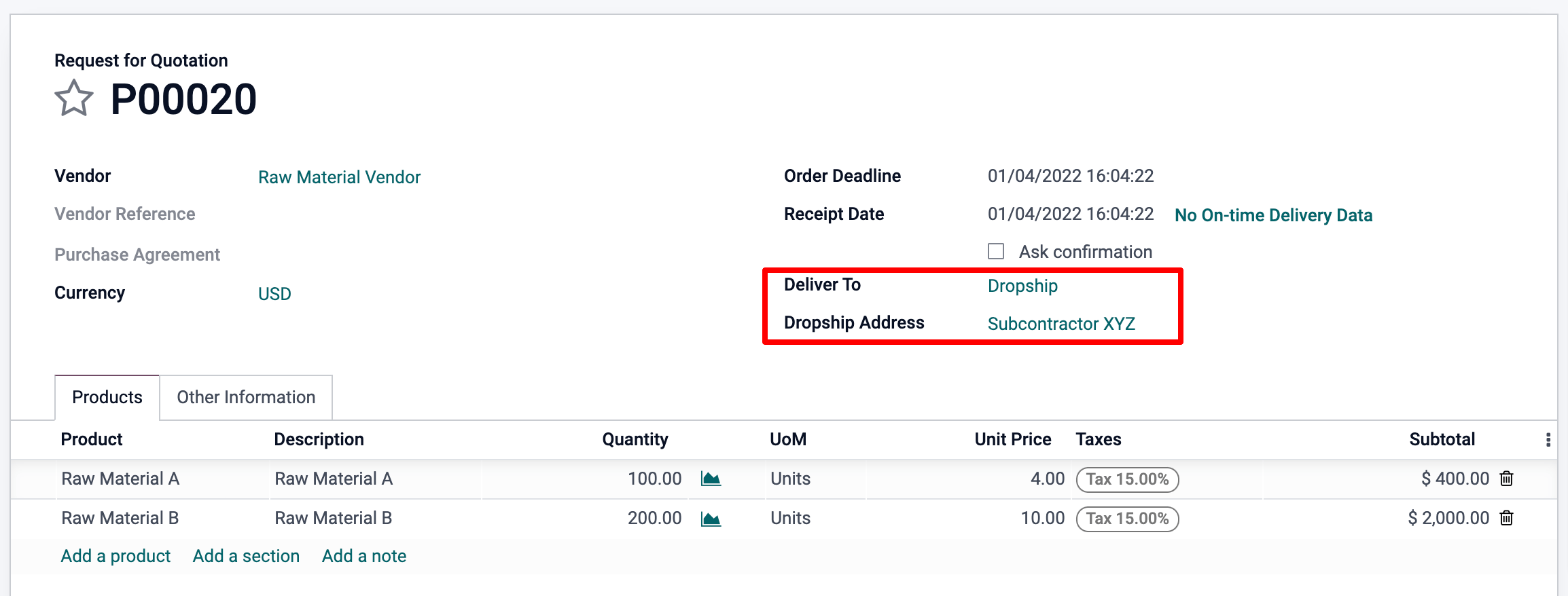

Now, if you want your vendor to resupply your subcontractor directly, you must choose the ‘Dropship Subcontractor on Order’ option instead. In order for this option to be active on the product form, you must first activate the dropship option from . Once the PO to the subcontractor is validated, this route will create a dropship RFQ from your vendor to that subcontractor. You then just need to review and validate it.

Note that the buy route is not selected in this case, as the dropship route is a buy route already.

Finally, if you want to track the stock of these raw materials at your subcontracting location(s), then you must activate Multi-locations in .

From the location form, you are then able to access the Current Stock.

手动补给¶

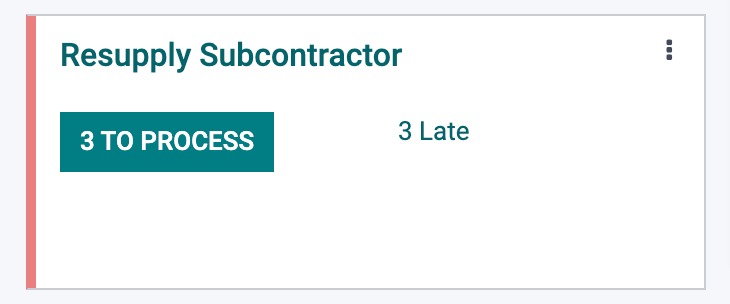

You can also choose to replenish your subcontractors manually.

If you want to send components to your subcontractor at your own convenience, select the ‘Resupply Subcontractor’ Operation Type from the Inventory Module, and create a picking, specifying to which subcontractor you are delivering to.

Alternatively, you can also manually ask your vendor to resupply your subcontractor by creating a dropship type PO, with your subcontractor set as the delivery address.